Project Description

Gas chromatograph PT-GC9720PLUS

1. System capability

- Assembly simultaneously: 2 inlets+3 detectors(FID, TCD, ECD, FPD optional)

- Independent split cold-trap and septum collecting trap,

Carrier gas control mode: pressure, flow, programming pressure, programming flow,

Programming pressure/flow/linear speed: max 8 steps,

Maintenance tracking reminder, intelligent regular maintenance plan,

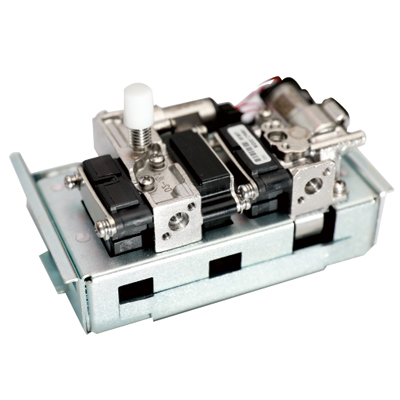

2. EPC/AFC gas system

- Full AFC/EPC, 6 AFC module with 18-channel AFC/EPC independent control,

AFC/EPC pressure accuracy 0.001psi, Retention time RSD <=0.02%, Peak area RSD <=1.0%, - Carrier and makeup gas settings selectable for He, H2, N2 and Ar

- Psi, KPa, Bar units selectable

- Pressure control range: 1~600KPa, Pressure accuracy: 0.01Psi, Programmable pressure ramp RSD ≤0.5%

- Flow rate control range: 0~600ml/min, flow rate accuracy: 0.1ml/min, flow rate RSD≤0.1%

- Flow sensor accuracy: ≤±3%, detector module accuracy: ≤±7%

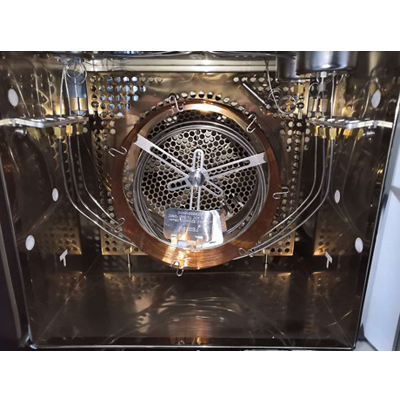

3. Column oven—Excellent temperature control system

- Column oven dimension: 278×310×165mm=14.2L, accommodate up to 2pcs 105m×0.53mm ID capillary column

- Temp. control range: RT+5℃~450℃(0.1℃ increment)

- Standard cool-down mode 450—50℃<=5min

- Optional quick cool-down mode 450—50℃<=3.5min

- Scientific inner heating interchange to achieve high consistency in between front and back column heating distribution

- Reproducible temp. ramp process in column oven to achieve good retention time RSD

- Max temp.-ramp rate: 120 ℃/min

- Programming temp.-ramp: 30 steps

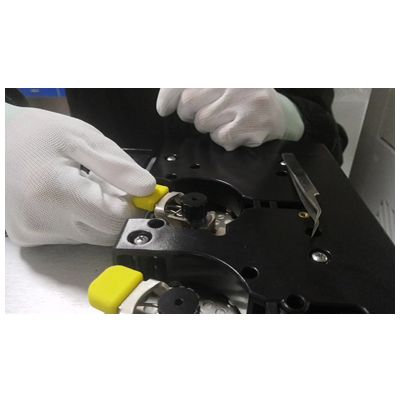

4. Inlets

- Packed purge injection port(PPIP)

- Split/splitless capillary port(S/SL)

- Max temperature: 450℃

- Split ratio: 4500:1

- Gas saver mode to reduce gas consumption without compromising performance

- Programmable temp./pressure ramp: 8 steps

- Manual dismount in 10s to make liner replacement easier

- Intelligent tip to record and remind replacement/maintenance of septum, liner and split cold-trap

5. Detectors

| Detector | Max operating temp. | Limit of detection | Baseline noise | Baseline drift (after 2hrs stabilization) | Linear dynamic range |

|---|---|---|---|---|---|

| FID | 450℃ | ≤3.0×10^-12g/s (N-C16) | ≤2×10^-14 A | 5×10^-14 A/30 min | ≥10^7 |

| TCD | 400℃ | ≥10000mV.ml/mg (N-C16) | ≤30uV | ≤100uV/30min | ≥10^4 |

| ECD | 400℃ | ≤ 3×10^-14g/ml (γ-666) | ≤20uV | ≤50uV/30min | ≥10^4 |

| FPD | 400℃ | S: ≤2.0×10^-11g/s P: ≤5.0×10^-13g/s or 2.0×10^-13g/s | S: ≤2×10^-13A P: ≤8×10^-13A | S: ≤1×10^-12 A/30min P: ≤2×10^-12 A/30min | S: ≥10^2 P: ≥10^3 |

6. Autosampler

- Single FL1092T, 16-vial autosampler

- Double FL1092T, double-tower independent asynchronous control or synchronous control to improve analysis efficiency

- Single/double FL1092T+FL1092C, 150-vial autosampler, heating/barcode scan/stirring and whole plate cooling/heating are optional

7. Multi-valve system

- Multi-valve/multi-column available to customize per different application, max 4 external valve can be installed

- One-time injection for complete gas analysis

- High stability and low valve switchover fluctuation

8. Workstation and data communications

- LAN

- Windows 10/7 support

- Signal capture from 2 detectors simultaneously

- Sampling frequency: 100Hz

- Sampling speed: 50 times/sec

- Unlimited peak quantity

- Self-diagnosis: intelligent automatic error identification and self-protection

- FL97PLUS software and Clarity V8.3 to fully support FDA-21 CFR PART 11

9. Basic info

- Votage: 220V±10%, 50Hz

- Power: 3000W

- Dimension: 645×500×555mm

- Net weight: 55KG